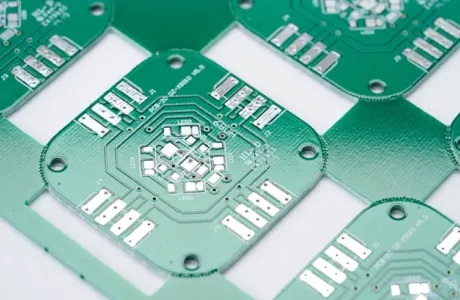

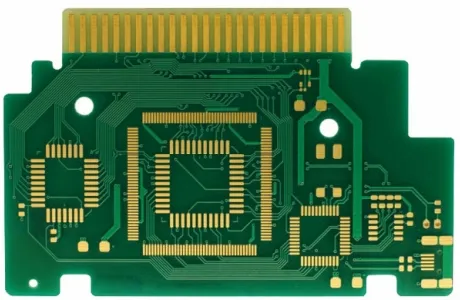

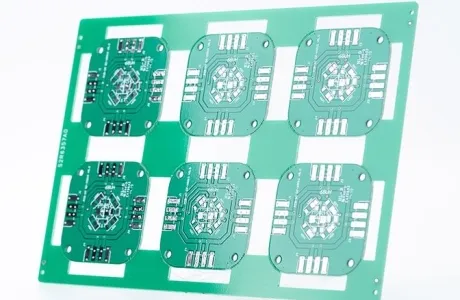

Double-sided Tin Spray FR4 Automotive PCB Circuit Board

Description :

Double-sided tin spray FR4 automotive PCB circuit board is a type of printed circuit board (PCB) that is commonly used in automotive applications. It has the features of high durability, improved signal integrity, and cost-effectiveness, making it widely used in various automotive systems.Product Details:

Double-sided Tin Spray FR4 Automotive PCB Circuit Board Introduction

Double-sided tin spray FR4 automotive PCB circuit board is a type of printed circuit board (PCB) that is commonly used in automotive applications. It is designed with two layers of copper traces and a layer of FR4 (Flame Retardant 4) substrate material. The tin spray refers to the surface treatment of the copper traces with a thin layer of tin, which provides protection against oxidation and improves solderability.

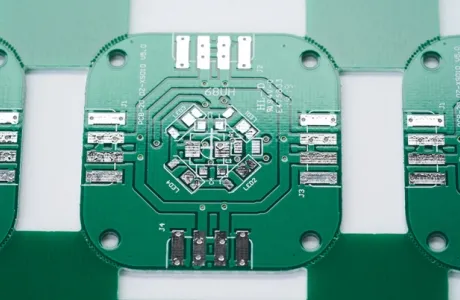

Double-sided Tin Spray FR4 Automotive PCB Circuit Board Parameter

| Number of layers | 2 |

| Substrate | FR4 TG150 |

| Thickness | 1.6mm |

| Surface Treatment | Lead-free spray tin |

| Special Process | impedance |

| Minimum aperture | 0.5mm |

| Inner layer line width and line spacing | / |

| Outer layer line width and line spacing | 19mil |

| Applications | Automotive systems |

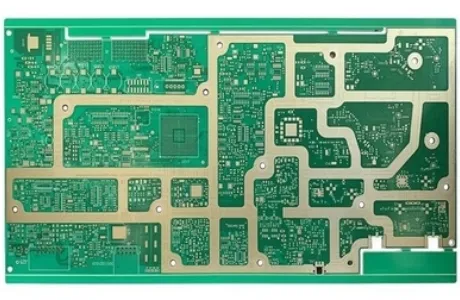

Double-sided Tin Spray FR4 Automotive PCB Circuit Board Features

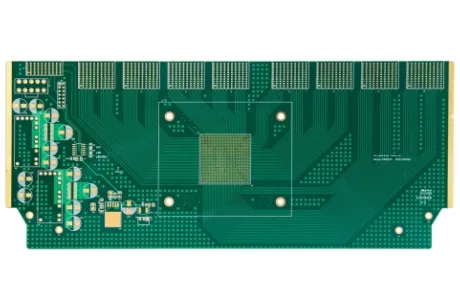

1. Durability: The FR4 substrate material provides excellent mechanical strength and resistance to heat, moisture, and chemicals, making it suitable for automotive applications that require long-term reliability.

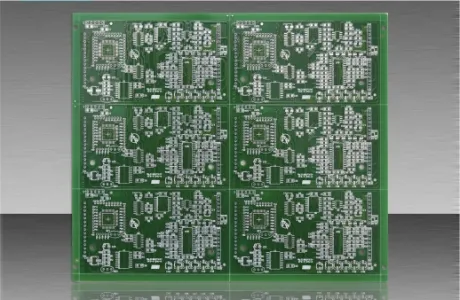

2. High Density: The double-sided design allows for increased circuit density, enabling more components to be placed on the board, which is essential for complex automotive systems.

3. Improved Signal Integrity: The use of double-sided boards helps reduce signal interference and noise, leading to improved signal integrity and overall performance of automotive electronics.

4. Cost-effective Solution: Double-sided PCBs are generally more cost-effective compared to multilayer boards, making them a preferred choice for automotive applications where cost optimization is important.

Double-sided Tin Spray FR4 Automotive PCB Circuit Board Applications

These circuit boards are widely used in automotive electronics due to their durability, reliability, and ability to withstand harsh operating conditions. They are used in various automotive systems such as engine control units (ECUs), powertrain control modules (PCMs), infotainment systems, and more.