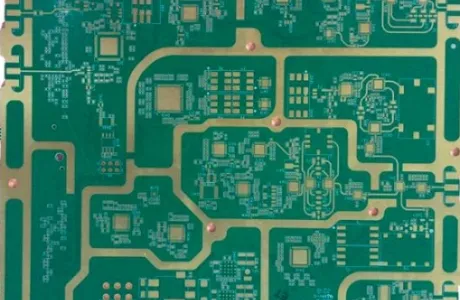

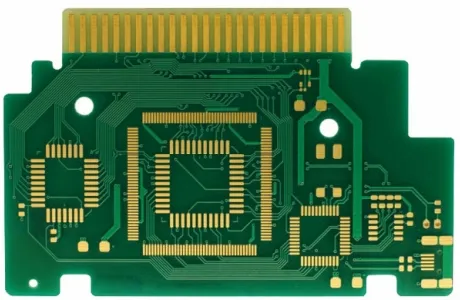

6-layer Immersion Gold Rogers+FR4 Mixed Pressure Communication PCB Board

Description :

6-layer immersion gold Rogers + FR4 mixed pressure communication PCB board is specially designed for communication devices like power amplifiers.Product Details:

6-layer Immersion Gold Rogers+FR4 Mixed Pressure Communication PCB Board Introduction

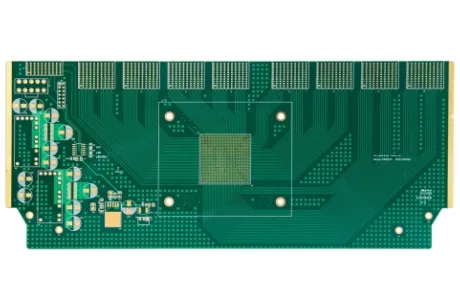

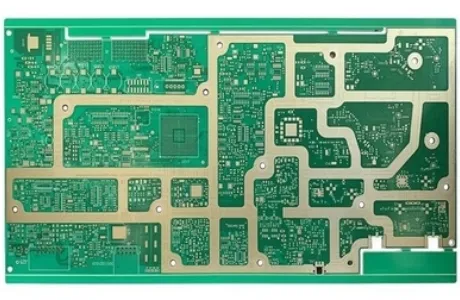

6-layer immersion gold Rogers+FR4 mixed pressure communication PCB board is a type of printed circuit board that combines Rogers laminate and FR4 material. It is designed for use in communication applications, particularly in wireless communication base stations and power amplifiers.

What Is Rogers?

Rogers laminate is a high-frequency material known for its excellent electrical performance. Different from the conventional PCB board—epoxy resin (FR4), it has no glass fiber in the middle and uses a ceramic base as the high-frequency material. It exhibits a stable dielectric constant over a broad frequency range and has low loss properties. Its dielectric constant thermal expansion coefficient is very consistent with copper foil, which can be used to improve the deficiencies of PTFE substrates. Therefore, it is very suitable for high-speed electronic design, commercial microwave, and radio frequency applications.

6-layer Immersion Gold Rogers+FR4 Mixed Pressure Communication PCB Board Parameter

| Number of layers | 6 |

| Substrate | Rogers 4350 + FR4 |

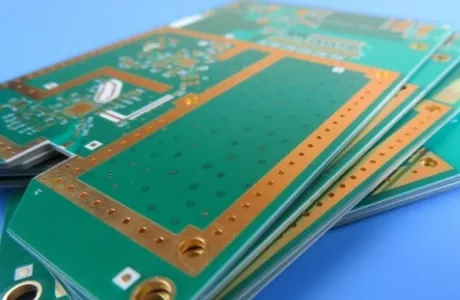

| Thickness | 2.3mm |

| Surface Treatment | Immersion Gold |

| Special Process | Mixed media |

| Minimum aperture | 0.6mm |

| Inner layer line width and line spacing | 5/5mil |

| Outer layer line width and line spacing | 7/7mil |

| Applications | Mainly used in communication power amplifiers |

6-layer Immersion Gold Rogers+FR4 Mixed Pressure Communication PCB Board Features

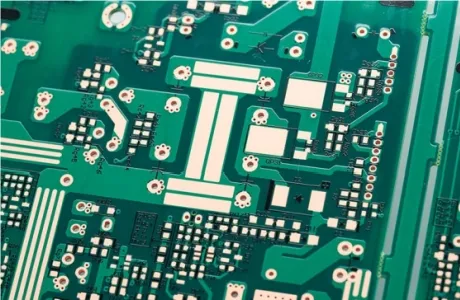

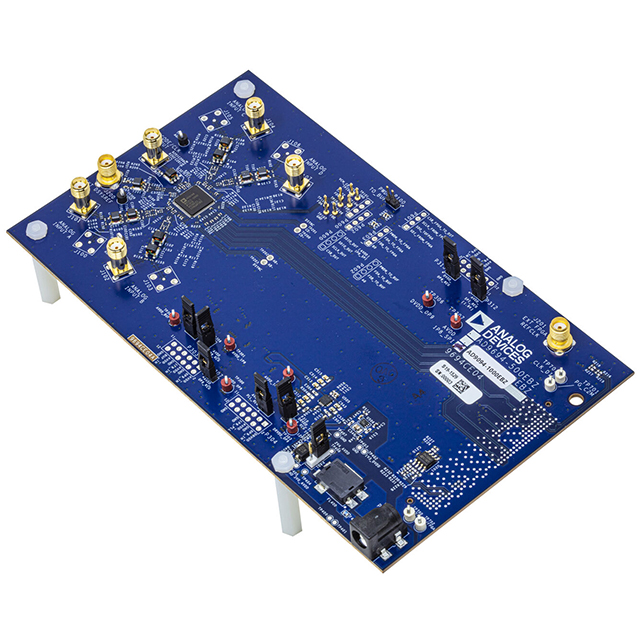

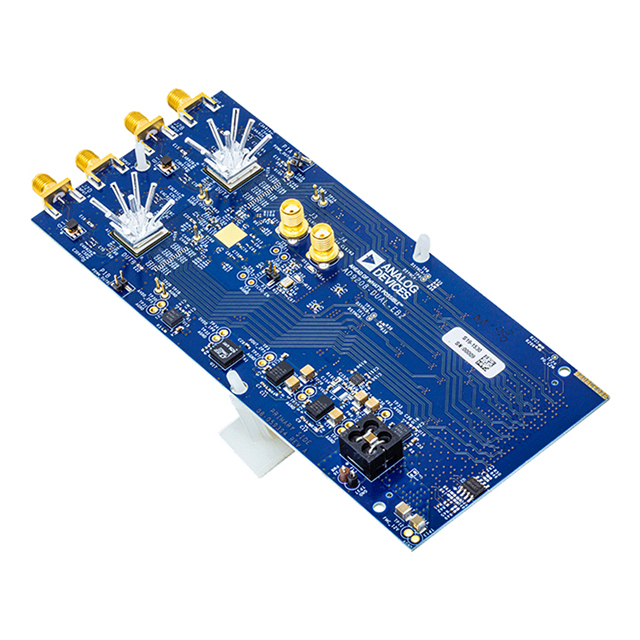

1. Hybrid Material Employment: This PCB board combines Rogers laminate and FR4 material. Rogers laminate is known for its excellent electrical performance, while FR4 is widely used for its mechanical strength and electrical insulation properties.

2. Electrical Performance Optimization: The use of Rogers laminate selectively in critical signal layers helps optimize the electrical performance of the PCB.

3. Cost Reduction: The combination of Rogers laminate and FR4 allows for cost reduction compared to using only high-frequency materials.

4. Immersion Gold Surface Finish: The PCB board is finished with immersion gold, which provides a smooth and reliable surface for component soldering.

5. Mature Mix Pressure Process: The mature mixed pressure process realizes the mixing of FR-4 and high-frequency materials, and saves the material cost for customers under the premise of achieving the high-frequency performance of the products.

6-layer Immersion Gold Rogers+FR4 Mixed Pressure Communication PCB Board Applications

These boards are commonly used in communication devices such as wireless communication base stations, power amplifiers, and communication modules.