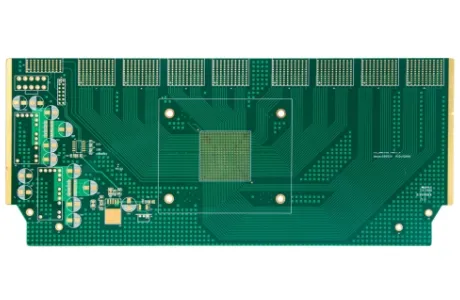

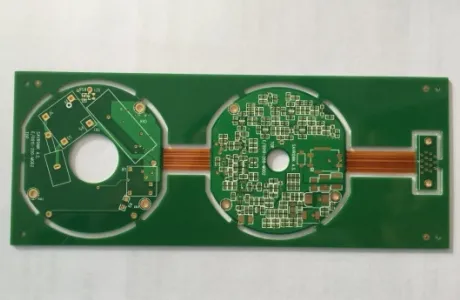

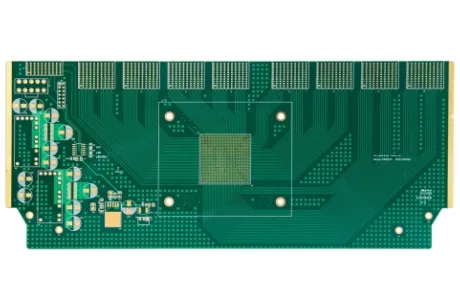

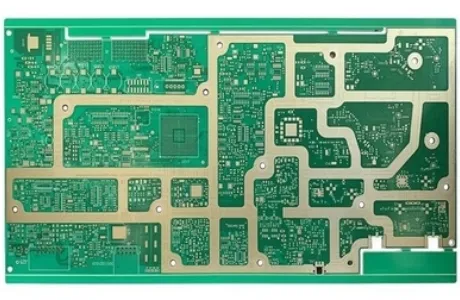

8-layer Immersed Gold Industrial Control Soft and Hard Combination PCB Circuit Board

Description :

8-layer immersed gold industrial control soft and hard combination PCB circuit board is a printed circuit board specially used in industrial control systems to monitor and control various parameters such as temperature, humidity, pressure, speed, and other process variables. These PCBs are typically ruggedized and designed to withstand harsh industrial environments such as those found in manufacturing plants, chemical plants, and industrial machinery.Product Details:

What Is 8-layer Immersed Gold Industrial Control Soft and Hard Combination PCB Circuit Board?

8-layer immersed gold industrial control soft and hard combination PCB circuit board is a type of printed circuit board (PCB) specially designed for use in industrial control applications like automation systems, robotics, power electronics, and other industrial equipment.

Materials Used for Fabricating 8-layer Immersed Gold Industrial Control Soft and Hard Combination PCB Circuit Board

Substrates

Substrates like glass-epoxy materials help to insulate heat and signals. This helps you handle the stackup better, even in high-pressure applications. Substrate materials have a great glass transition temperature that maintains the solidness of the PCB stack-up.

Conductive Materials

Copper is the most effective conductive material utilized in the fabrication process of the layer stack. This material is an ideal option since it is a good conductor of heat, allowing proper signal transfers and minimizing heat accumulation on the device. Copper is also a cheaper alternative to other materials like silver and gold, which are expensive.

8-layer Immersed Gold Industrial Control Soft and Hard Combination PCB Circuit Board Parameter

| Number of layers | 8 |

| Substrate | FR4 |

| Thickness | 1.6mm |

| Surface Treatment | Immersion Gold |

| Special Process | / |

| Stacking Layers | 2R+2F+2F+2R |

| Minimum aperture | 0.2mm |

| line width line spacing | 5/5mil |

| Applications | specifically designed for industrial control systems |

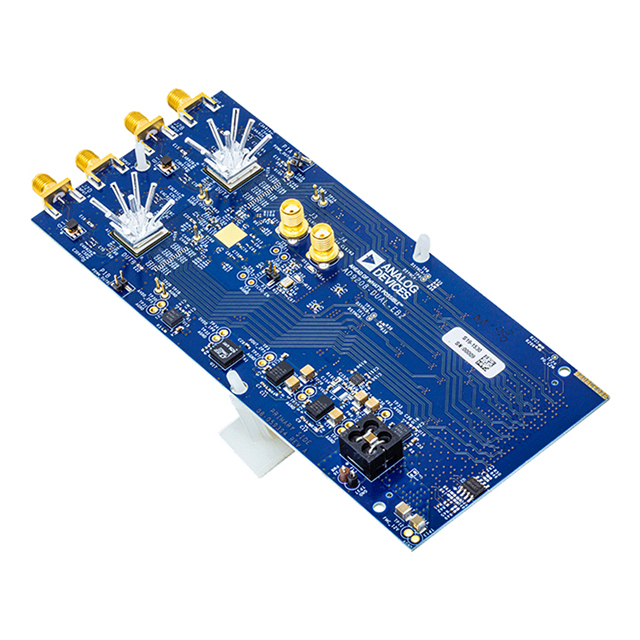

8-layer Immersed Gold Industrial Control Soft and Hard Combination PCB Circuit Board Features

1. 8 layer Structure: The PCB consists of eight layers, allowing for complex circuit designs and increased routing space.

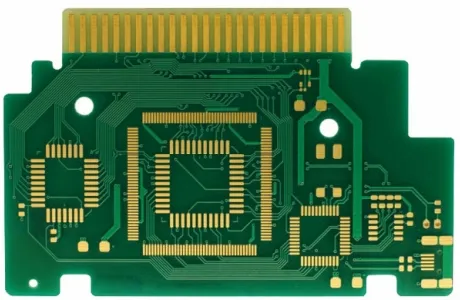

2. Immersion Gold Finish: The PCB utilizes immersion gold as a surface finish. Immersion gold creates a soft gold layer with good oxidation resistance and conductivity. This not only ensures good electrical conductivity throughout the board but also provides good oxidation resistance, protecting the PCB from corrosion and ensuring long-term reliability.

3. Wear Resistance: The hard gold finish on the gold fingers and edge contact points of the PCB provides abrasion resistance, preventing deterioration and ensuring reliable connections over multiple cycles.

4. Firm Soldering: The immersion gold board has only nickel gold on the pad, which allows for more secure soldering and a stronger bond with the copper layer.

5. Controlled Stress: Immersion gold is easier to control in terms of stress compared to gold plating, which can be beneficial for bonding products.

6. Signal Transmission: The immersion gold board has nickel-gold only on the pads, which ensures that the signal transmission in the copper layer is not affected, particularly in terms of skin effect.

7. High TG and Thick Copper: The high glass transition temperature (TG) and thick copper layers in the PCB enhance its thermal performance and current-carrying capacity.

8. High-Density Interconnect (HDI) Design: The use of HDI design techniques allows for increased circuit density and miniaturization, making the PCB suitable for high-end applications that require high-speed and high-frequency performance.

9. Industrial Control Applications: This PCB board is specifically designed for industrial control applications, which may include automation systems, robotics, power electronics, and other industrial equipment.

10. Customization and Manufacturing Capabilities: Gnee manufacturers specialize in fabricating these types of PCBs and offer customization services, allowing customers to tailor the design to their specific industrial control applications.

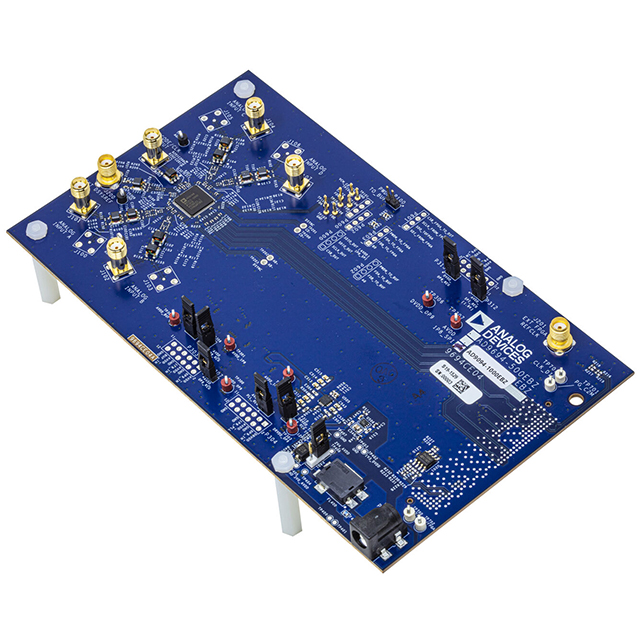

8-layer Immersed Gold Industrial Control Soft and Hard Combination PCB Circuit Board Applications

These PCBs are specifically designed for industrial control systems, including automation, robotics, manufacturing equipment, and process control systems. They provide reliable and efficient control for complex industrial processes.