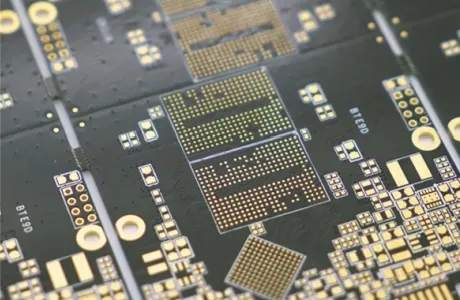

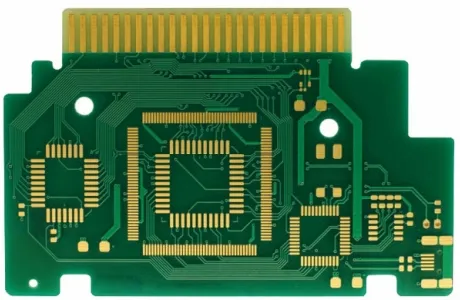

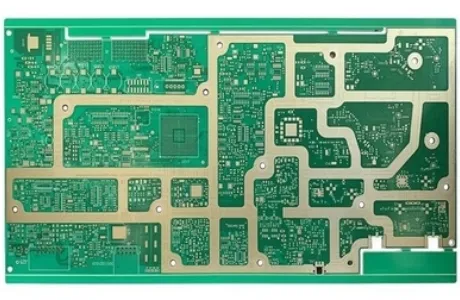

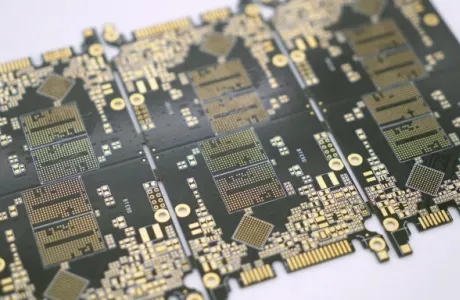

6-layer Immersion Gold FR4 Automotive Electronics PCB Board

Description :

6-layer immersion gold FR4 PCB board is a type of printed circuit board used in automotive electronics. Made of FR4 material, it has six layers and is coated with a thin layer of immersion gold to enhance corrosion resistance.Product Details:

6-layer Immersion Gold FR4 Automotive Electronics PCB Board Introduction

A 6-layer immersion gold FR4 PCB board is a type of printed circuit board used in automotive electronics. It consists of six layers of FR4 material, which is a flame-retardant fiberglass epoxy laminate. The board is coated with a thin layer of immersion gold as a surface treatment. Immersion gold is a process that applies a very thin layer of gold to the surface of the PCB, providing corrosion resistance and facilitating soldering operations.

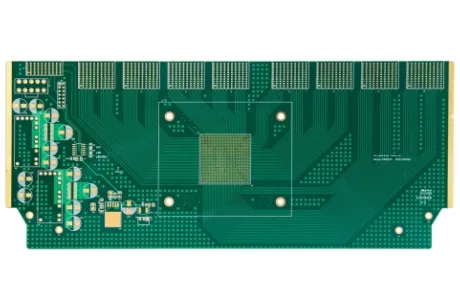

6-layer Immersion Gold FR4 Automotive Electronics PCB Board Parameter

| Number of layers | 6 |

| Substrate | FR4 |

| Thickness | 1.2mm |

| Surface Treatment | Lead-free spray tin |

| Special Process | Impedance |

| Minimum aperture | 0.2mm |

| Inner layer line width and line spacing | 4/3.5mil |

| Outer layer line width and line spacing | 4/4mil |

| Applications | car navigators and other automotive systems |

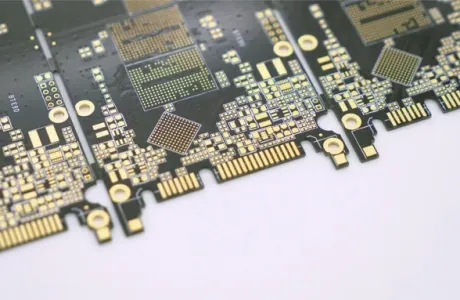

6-layer Immersion Gold FR4 Automotive Electronics PCB Board Features

1. Sturdy layers: This board has six layers, which allows for more complex circuit designs and better signal integrity.

2. Signal integrity: The use of a 6-layer PCB allows for better signal integrity, reducing the risk of signal interference and improving overall performance.

3. Complex circuit designs: The multiple layers of the PCB provide ample space for complex circuit designs, allowing for the integration of various components and functionalities.

4. Corrosion resistance: The immersion gold surface treatment provides excellent corrosion resistance, ensuring the longevity and reliability of the PCB in automotive environments.

5. Solderability: The immersion gold coating facilitates soldering operations, making it easier to assemble and repair the PCB.

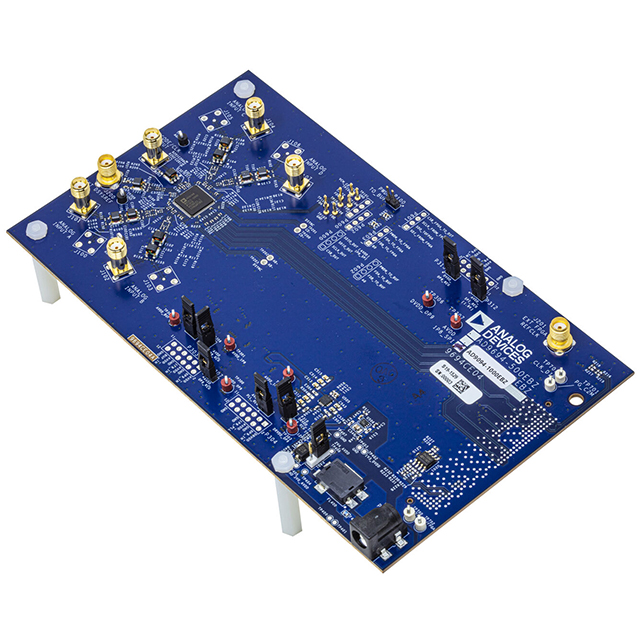

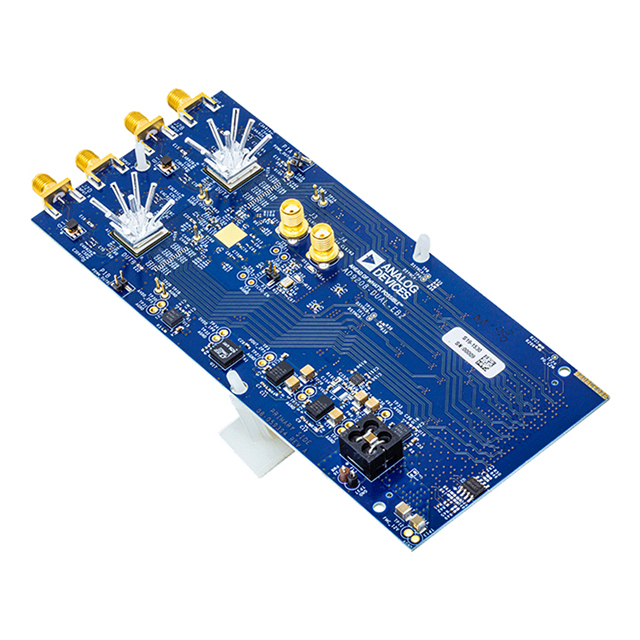

6. Wide application field: 6-layer immersion gold FR4 PCB boards are widely used in automotive electronics, as well as in other industries such as medical, industrial control, IoT, smart home, military, and aerospace.

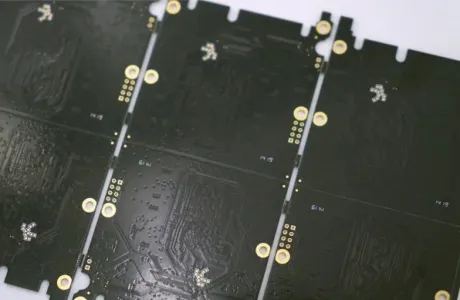

7. Special processes: The board may include special processes such as through-hole and blind buried via, allowing for more advanced and customized circuit designs.

8. Compatibility: FR4 is a widely used base material in the PCB industry, ensuring compatibility with various components and manufacturing processes.

9. Cost-effective solution: FR4 PCBs are generally cost-effective compared to other materials, making them a popular choice for automotive electronics applications.

6-layer Immersion Gold FR4 Automotive Electronics PCB Board Applications

These PCB boards are specifically designed for use in automotive electronics systems. They can be used in applications such as engine control units (ECUs), infotainment systems, advanced driver-assistance systems (ADAS), lighting systems, powertrain control modules, and more.