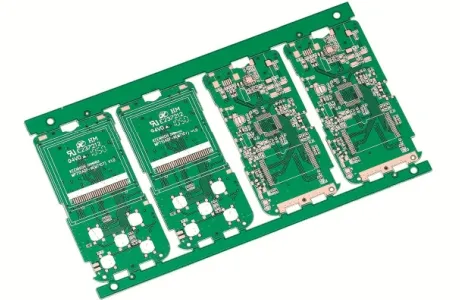

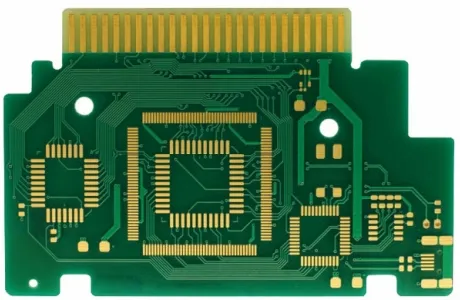

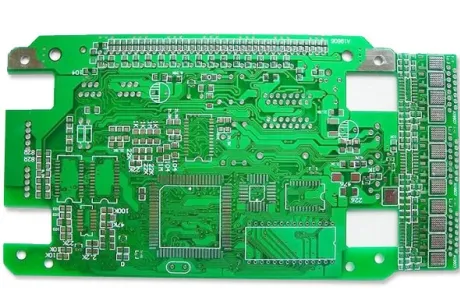

4-layer Spray Tin FR4 Automotive PCB Circuit Board

Description :

4-layer spray tin FR4 automotive PCB circuit board is a type of printed circuit board (PCB) that is specifically designed for automotive applications. The board is designed as a 4-layer structure, because 4-layer PCB is relatively simple and inexpensive, which is helpful to open up a new market. What's more, the surface finish of spray tin is for protection and solderability.Product Details:

What Is 4-layer Spray Tin FR4 Automotive PCB Circuit Board?

4-layer spray tin FR4 automotive PCB circuit board is a type of printed circuit board (PCB) that is specifically designed for automotive applications. It consists of multiple layers of FR4 material, which is a flame-retardant epoxy laminate commonly used as a base material for insulation in PCBs.

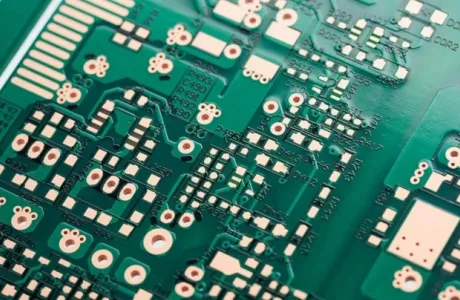

The term "spray tin" refers to the surface treatment of the PCB. Spray tin is one of the surface finishes used to protect the copper traces on the board from oxidation and provide a solderable surface. It involves applying a thin layer of tin onto the copper traces using a spray coating process.

4-layer Spray Tin FR4 Automotive PCB Circuit Board Parameter

| Number of layers | 4 |

| Substrate | FR4 |

| Thickness | 1.0mm |

| Surface Treatment | Lead-free spray tin |

| Special Process | impedance |

| Minimum aperture | 0.5mm |

| Inner layer line width and line spacing | 6/6mil |

| Outer layer line width and line spacing | 7/7mil |

| Applications | Automotive systems |

4-layer Spray Tin FR4 Automotive PCB Circuit Board Advantages

The 4-layer Spray Tin FR4 Automotive PCB Circuit Board offers several advantages. Here are some key benefits:

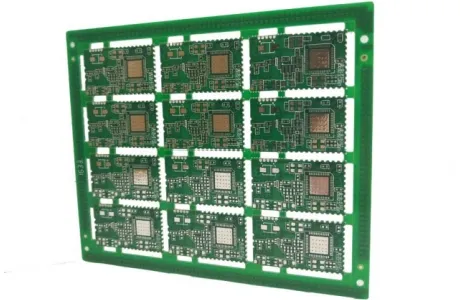

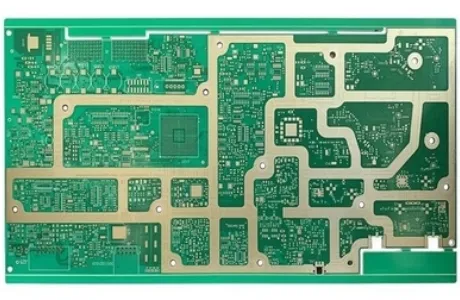

1. Enhanced Circuit Density: The use of multiple layers in a 4-layer PCB allows for increased circuit density. This means that more components can be placed on the board, making it suitable for complex automotive applications.

2. Improved Signal Integrity: The additional layers in a 4-layer PCB provide better signal integrity by reducing electromagnetic interference (EMI) and crosstalk between traces. This is particularly important in automotive applications where reliable communication between different components is crucial.

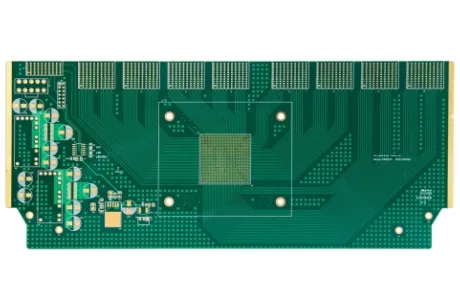

3. Increased Design Flexibility: The multiple layers in a 4-layer PCB provide greater design flexibility. It allows for the separation of power and ground planes, which helps in reducing noise and improving the overall performance of the circuit.

4. Better Thermal Management: The additional layers in a 4-layer PCB can be used for thermal management purposes. The heat generated by components can be efficiently dissipated through the use of thermal vias and copper planes, ensuring the reliability and longevity of the automotive circuit board.

5. Space Efficiency: The use of multiple layers allows for a more compact design, saving valuable space in automotive applications where size constraints are common. This can be particularly beneficial in modern vehicles where space is at a premium.

6. Cost-effective solution: FR4 is a widely used and cost-effective material for PCB manufacturing. It offers good electrical and environmental properties at a reduced cost This makes a 4-layer Spray Tin FR4 Automotive PCB Circuit Board an economical choice for automotive applications.

4-layer Spray Tin FR4 Automotive PCB Circuit Board Applications

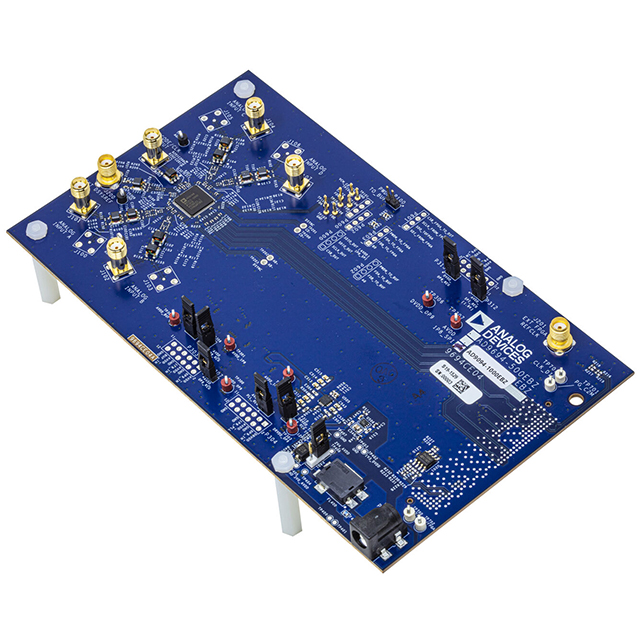

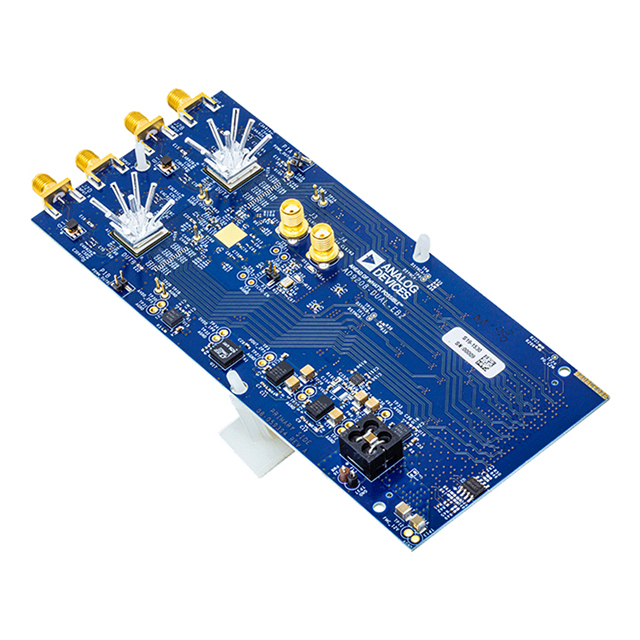

Some specific applications of 4-layer spray tin FR4 PCB circuit boards in the automotive industry include:

1. Auto-counters: 4-layer FR4 PCBs with 4oz copper and immersion tin surface finish are used in auto-counters.

2. Automotive electronics: FR4 PCBs are widely used in various electronic systems and components in automobiles, such as engine control units (ECUs), infotainment systems, instrument clusters, powertrain systems, and more.

3. PCMCIA: FR4 material is applicable for PCMCIA applications in the automotive industry.