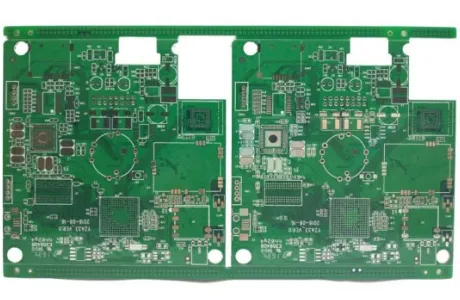

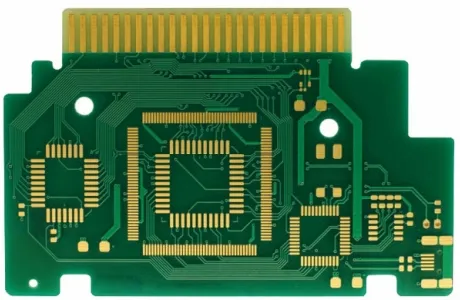

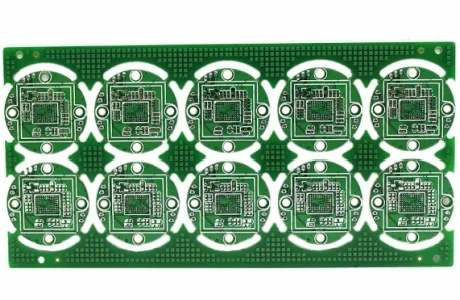

4-layer Spray Tin FR4 Automotive Electronic PCB Board

Description :

A 4-layer spray tin FR4 automotive electronic PCB board is a type of printed circuit board (PCB) used in automotive electronic systems. It has the features of 4-layer structure, signal integrity, and electrical insulation, suitable for a wide range of automotive electronic system applications.Product Details:

4-layer Spray Tin FR4 Automotive Electronic PCB Board Introduction

A 4-layer spray tin FR4 automotive electronic PCB board is a type of printed circuit board (PCB) used in automotive electronic systems. It is designed specifically for automotive applications and has four layers of conductive material separated by insulating layers.

The term "FR4" refers to the type of material used as the base substrate for the PCB. FR4 is a flame-retardant epoxy glass cloth laminate material that provides good electrical insulation properties, high flatness, and excellent mechanical strength.

The "spray tin" refers to the surface finish treatment applied to the PCB. Spray tin is a type of surface finish that involves applying a thin layer of tin onto the copper traces and pads of the PCB. This surface finish helps protect the copper from oxidation and provides a solderable surface for component attachment.

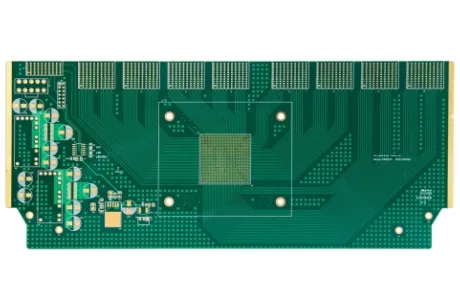

4-layer Spray Tin FR4 Automotive Electronic PCB Board Parameter

| Number of layers | 4 |

| Substrate | FR4 |

| Thickness | 1.2mm |

| Surface Treatment | Lead-free spray tin |

| Special Process | Impedance, Metal edging |

| Minimum aperture | 0.3mm |

| Inner layer line width and line spacing | 9/9mil |

| Outer layer line width and line spacing | 5/3mil |

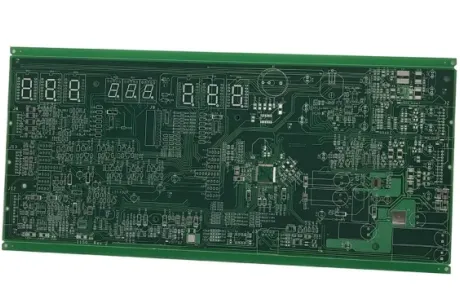

| Applications | driving recorder, camera, and other automotive systems |

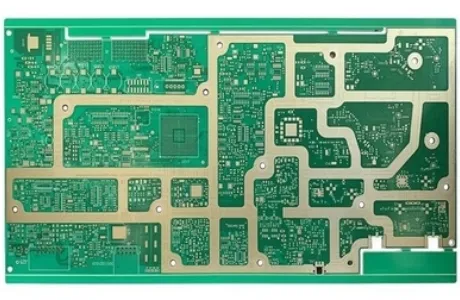

4-layer Spray Tin FR4 Automotive Electronic PCB Board Features

1. FR4 Material: The base material used in a 4-layer spray tin FR4 automotive electronic PCB board is FR4, which is a flame-retardant epoxy glass cloth laminate material. FR4 is widely used in PCB production due to its good specifications and cost-effectiveness.

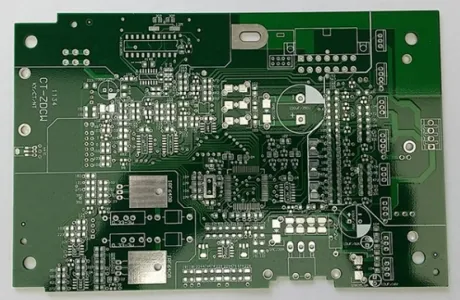

2. 4-layer Structure: 4-layer PCB is made by lamination based on the double-sided PCB. During the lamination, copper foil and PP are added to the two sides of the double-sided PCB, and then the 4-layer PCB is formed by high-temperature pressing.

3. Surface Finish: The surface finish treatment applied to a 4-layer spray tin FR4 automotive electronic PCB board is spray tin. Spray tin is a type of surface finish that involves applying a thin layer of tin onto the copper traces and pads of the PCB.

4. Automotive Applications: These PCB boards are specifically designed for automotive electronic systems. They are built to withstand the harsh conditions and requirements of automotive environments, including temperature variations, vibrations, and electrical noise.

5. Signal Integrity: 4-layer spray tin FR4 automotive electronic PCB boards offer good signal integrity, ensuring reliable communication between components and minimizing signal loss or interference.

6. Thermal Stability: FR4 PCBs, including 4-layer spray tin FR4 automotive electronic PCB boards, provide enhanced thermal stability. This allows them to withstand the heat generated by automotive electronics without compromising performance.

7. Electrical Insulation: FR4 material used in these PCB boards provides excellent electrical insulation properties, ensuring proper isolation between different circuit layers and preventing short circuits.

8. Mechanical Strength: FR4 PCBs are known for their excellent mechanical strength, making them durable and resistant to physical stress and impact.

9. Versatility: 4-layer spray tin FR4 automotive electronic PCB boards can be used for various automotive applications, including engine control units, infotainment systems, sensors, and more.

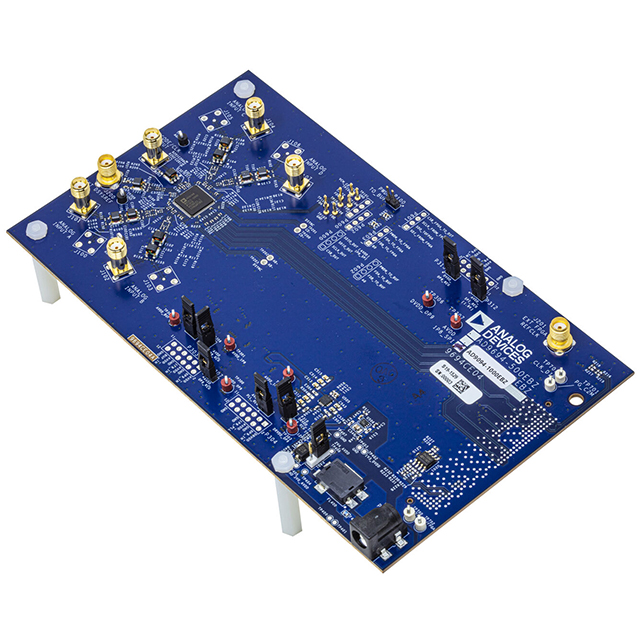

4-layer Spray Tin FR4 Automotive Electronic PCB Board Applications

4-layer spray tin FR4 automotive electronic PCB board finds applications in various automotive electronic systems. Here are some common applications:

1. Engine Control Units (ECUs): These PCB boards are used in the control units of automotive engines. They help manage and regulate engine functions such as fuel injection, ignition timing, and emissions control.

2. Infotainment Systems: 4-layer spray tin FR4 PCB boards are utilized in infotainment systems found in modern vehicles. These systems include features like touchscreen displays, audio systems, navigation systems, and connectivity options.

3. Sensors: Automotive sensors, such as those used for temperature, pressure, proximity, and motion detection, often rely on 4-layer spray tin FR4 PCB boards for their circuitry and signal processing.

4. Safety Systems: PCB boards with spray tin FR4 construction are employed in various safety systems, including anti-lock braking systems (ABS), airbag control units, traction control systems, and electronic stability control.

5. Powertrain Control Modules: These PCB boards are used in powertrain control modules, which manage the operation of the vehicle's powertrain components, including the engine, transmission, and drivetrain.

6. Lighting Systems: Automotive lighting systems, such as LED headlights, taillights, and interior lighting, utilize 4-layer spray tin FR4 PCB boards for controlling and powering the lighting elements.

7. Advanced Driver Assistance Systems (ADAS): ADAS features like adaptive cruise control, lane departure warning, and collision avoidance systems rely on PCB boards for their electronic control and sensor integration.

8. Battery Management Systems: Electric and hybrid vehicles use 4-layer spray tin FR4 PCB boards in their battery management systems, which monitor and control the charging, discharging, and overall performance of the vehicle's battery pack.