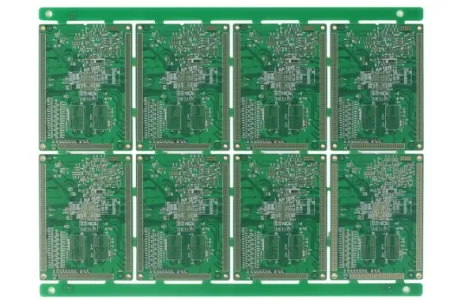

10-layer Immersion Gold FR4 Industrial Control PCB Board

Description :

10-layer immersion gold FR4 industrial control PCB board is a printed circuit board (PCB) that is designed for use in industrial control applications. It uses FR4 materials as substrates, offering great fire resistance, mechanical strength, and electrical insulation. This is why it’s popular in industrial applications to provide precise control and high automation.Product Details:

10-layer Immersion Gold FR4 Industrial Control PCB Board Introduction

10-layer immersion gold FR4 industrial control PCB board is a printed circuit board (PCB) that is designed for use in industrial control applications. It is made using FR4 as the base material, which is a type of fiberglass-reinforced epoxy laminate that offers good mechanical strength, electrical insulation, and fire resistance.

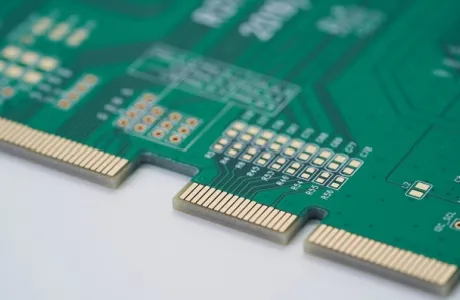

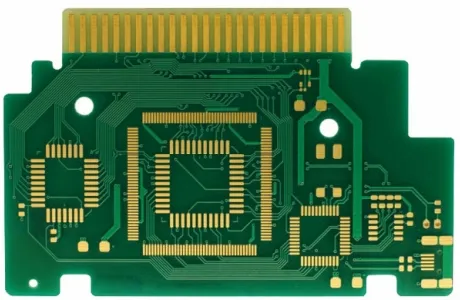

Immersion gold is a process applied to the board by using electroplating and immersion. Gold is preferred as a surface finish option for its operational stability, durability, and strength. It provides a reliable and corrosion-resistant surface for the 10-layer immersion gold PCB board.

10-layer Immersion Gold FR4 Industrial Control PCB Board Parameter

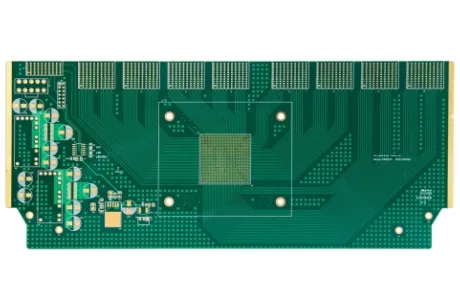

| Number of layers | 10 |

| Substrate | FR4 |

| Thickness | 1.0mm |

| Surface Treatment | Immersion Gold |

| Special Process | / |

| Minimum aperture | 0.3mm |

| Inner layer line width and line spacing | 4/3.5mil |

| Outer layer line width and line spacing | 4.5/2.5mil |

| Applications | specifically designed for industrial control systems like industrial handheld automotive diagnostic instrument |

10-layer Immersion Gold FR4 Industrial Control PCB Board Features

10-layer printed circuit boards offer quite several benefits when using them.

1. Base Material: The PCB board is made using FR4 as the base material. FR4 is a fiberglass-reinforced epoxy laminate known for its resistance to fire, good mechanical strength, and excellent electrical insulation.

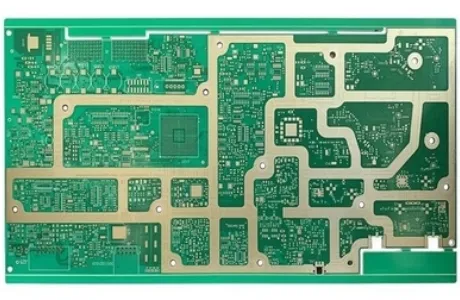

2. Complex Circuit Designs: 10 layers allow for complex circuit designs and increased functionality. The multiple layers provide ample space for routing traces and accommodating components, making it suitable for industrial control applications that require advanced circuitry.

3. Great Durability: The immersion gold surface finish enhances the durability of the PCB. It protects the underlying copper traces and components during storage and operation, reducing the risk of damage or degradation.

Also, the 10-layer boards are very strong and will survive the impact of external heat and pressure without damage.

4. High Strength: Gold as a surface finish option provides strength to the printed circuit board. It helps maintain the integrity of the PCB, especially in industrial control applications where reliability is crucial.

5. Good Mechanical Strength: FR4, the base material used in the PCB, offers good mechanical strength. This makes the PCB robust and capable of withstanding the demands of industrial control environments.

6. Electrical Insulation: FR4 is known for its excellent electrical insulation properties. It helps prevent short circuits and ensures proper signal transmission within the PCB.

7. Light in Weight: As much as the 10-layer PCB boards may have numerous layers, it is still light in weight.

8. Increased Power: An increase in the number of layers simply means an increase in the surface area thus more space for further component inputs.

10-layer Immersion Gold FR4 Industrial Control PCB Board Applications

The 10-layer immersion gold FR4 PCB board is specifically designed for industrial control systems. Here are some common applications:

1. Industrial Equipment: Industrial control PCBs are used in assembly machines, presses, ramps, and other equipment used in the manufacturing industry. These PCBs enable automation, improve precision, and provide control over various processes.

2. Custom Industrial Applications: Industrial control PCBs can be tailored to specific industrial applications based on the requirements of the equipment or system. They can be designed to withstand high-power applications and demanding environments and provide precise control.