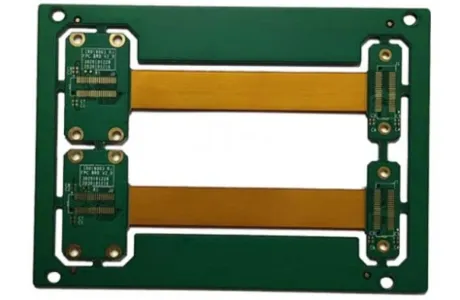

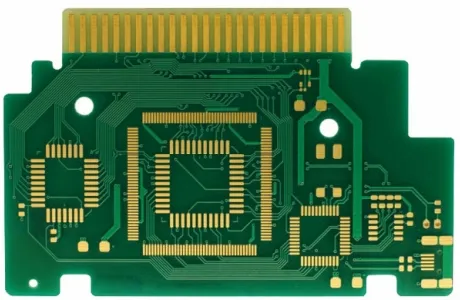

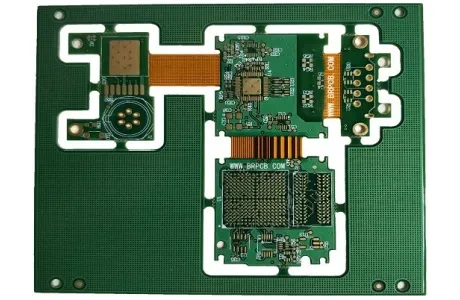

8-layer Immersion Gold Medical Soft-hard Combination PCB Board

Description :

8-layer Immersion Gold Medical Soft-hard Combination PCB Board is a specialized type of PCB used in medical electronics. It offers benefits such as good conductivity, oxidation resistance, and reliable solderability. These characteristics make it suitable for medical applications that require high-performance and reliable PCBs.Product Details:

8-layer Immersion Gold Medical Soft-hard Combination PCB Board

8-layer Immersion Gold Medical Soft-hard Combination PCB Board is a type of printed circuit board (PCB) that is used in medical applications. It has specific characteristics and features that make it suitable for medical electronics.

Benefits of Immersion Gold

Immersion gold has several advantages that make it suitable for medical applications. Here are some key benefits:

1. Conductivity: Gold is highly conductive, which ensures good electrical performance in the PCB.

2. Oxidation Resistance: Immersion gold provides good oxidation resistance, protecting the copper contacts and plated through-holes from oxidation.

3. Solderability: The soldering on the lines of an immersion gold board is more firmly combined with the copper layer, ensuring reliable solder joints.

4. Flatness: Immersion gold boards have better flatness, which is important for applications requiring higher flatness.

8-layer Immersion Gold Medical Soft-hard Combination PCB Board Parameter

| Number of layers | 8 |

| Substrate | FR4 |

| Thickness | 1.6mm |

| Surface Treatment | Immersion Gold |

| Special Process | / |

| Stacking Layers | 1R+2R+2F+1F |

| Minimum aperture | 0.2mm |

| line width line spacing | 4/4mil |

| Applications | specifically designed for use in medical devices like medical ventilators

|

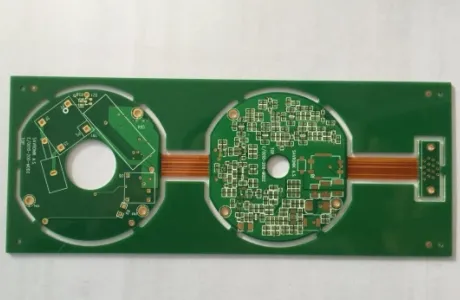

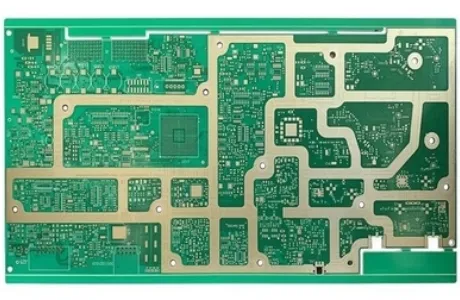

8-layer Immersion Gold Medical Soft-hard Combination PCB Board Production

The production of 8-layer immension gold medical soft-hard combination PCB board requires multiple steps, including design, board making, board copying, lamination, drilling, electroplating, circuit forming, welding, etc.

Among them, design is the first step, and the size, number of layers, materials, layout, etc. of the circuit board need to be determined according to product requirements. Board making is to produce designed circuit boards. Commonly used methods include etching and photolithography. Electroplating involves covering the inside and outside of a hole with a layer of metal to create a conductive layer. Line forming is the shaping of metal leads for subsequent soldering. Finally, welding is the soldering of electronic components to the circuit board, completing the entire manufacturing process.

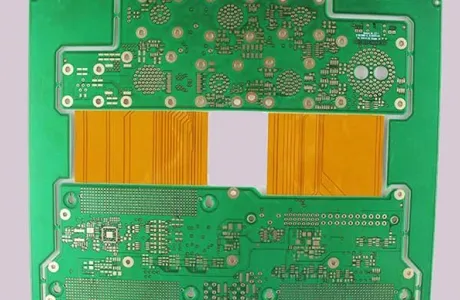

8-layer Immersion Gold Medical Soft-hard Combination PCB Board Features

8-layer Immersion Gold Medical Soft-hard Combination PCB Board has several features that make it suitable for medical applications. Here are some key features:

1. Immersion Gold Surface Finish: The PCB board is coated with immersion gold, which provides good conductivity, oxidation resistance, and solderability.

2. 8-Layer Design: The PCB board consists of 8 layers, allowing for more complex circuitry and higher density of components.

3. High TG (Glass Transition Temperature): The PCB board is designed to have a high TG, which means it can withstand higher temperatures without losing its mechanical and electrical properties.

4. HDI (High-Density Interconnect) Design: The PCB board utilizes HDI technology, which allows for higher density of components and smaller vias.

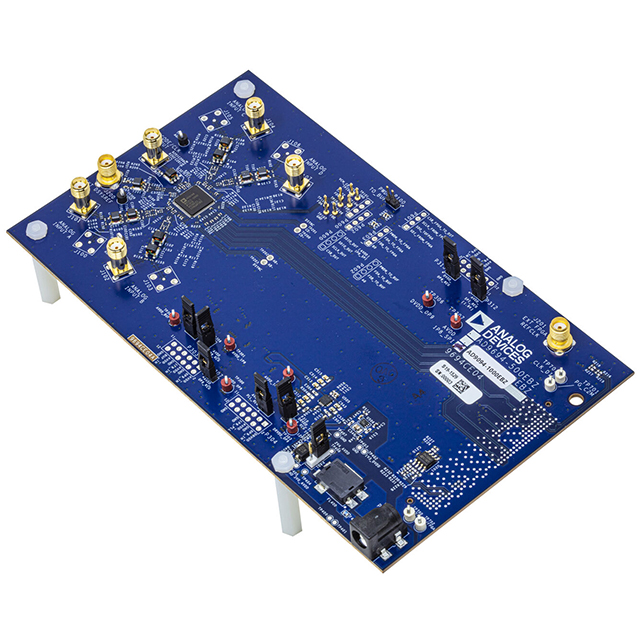

5. Conductivity: The immersion gold surface finish provides excellent conductivity, ensuring reliable electrical performance in medical electronics.

6. Oxidation Resistance: The immersion gold coating offers good oxidation resistance, protecting the copper contacts and plated through-holes from oxidation.

7. Solderability: The soldering on the lines of an immersion gold board is more firmly combined with the copper layer, ensuring reliable solder joints.

8. Flat Surface: Immersion gold boards have a flat surface, which is important for applications requiring higher flatness.

9. Reliability: The combination of immersion gold surface finish, soft gold, high TG, thick copper, and HDI design makes this PCB board highly reliable for medical applications that require consistent performance.

10. Reduce Radiation: This type of PCB helps to get rid of any radiation that might occur in high-speed applications. 8 layers PCBs get rid of electromagnetic interference radiation.

11. Suitable for Medical Electronics: The combination of immersion gold surface finish, soft gold, high TG, thick copper, and HDI design makes this PCB board suitable for medical applications requiring high performance, reliability, and compact design.

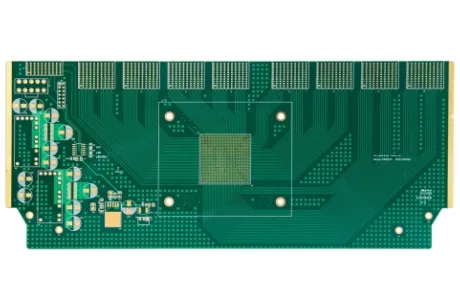

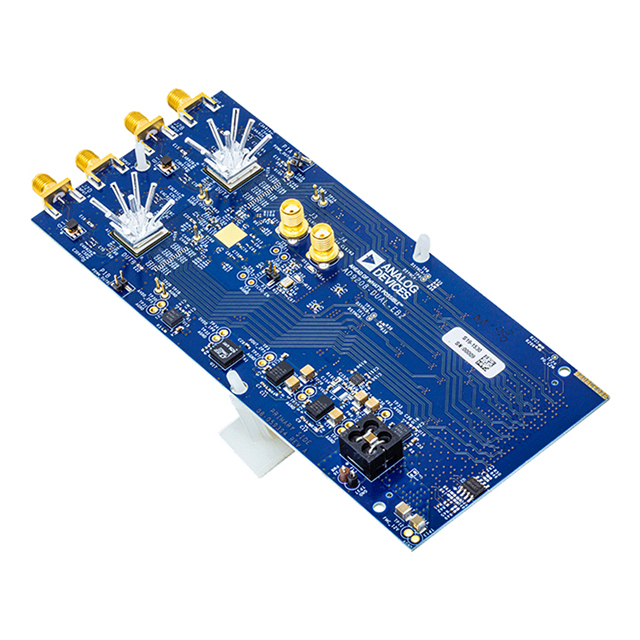

8-layer Immersion Gold Medical Soft-hard Combination PCB Board Applications

An 8-layer Immersion Gold Medical Soft-hard Combination PCB Board finds applications in various medical electronic devices and systems. Here are some common applications:

1. Medical Imaging Equipment: These PCB boards are used in medical imaging devices such as X-ray machines, CT scanners, MRI machines, and ultrasound systems. They provide the necessary circuitry for image acquisition, processing, and display.

2. Patient Monitoring Systems: PCB boards with soft-hard combination construction are used in patient monitoring systems, including ECG monitors, pulse oximeters, blood pressure monitors, and vital sign monitors. They enable accurate data acquisition and real-time monitoring of patient's health parameters.

3. Medical Diagnostic Instruments: These PCB boards are utilized in medical diagnostic instruments like laboratory analyzers, DNA sequencers, and blood glucose meters. They facilitate precise measurement, analysis, and interpretation of medical samples and data.

4. Implantable Medical Devices: PCB boards with soft-hard combination construction are used in implantable medical devices such as pacemakers, defibrillators, neurostimulators, and cochlear implants. They provide the necessary circuitry for device functionality and communication with external systems.

5. Medical Robotics: PCB boards are employed in medical robotic systems used in surgical procedures, rehabilitation, and patient care. They enable precise control, feedback, and communication in robotic-assisted surgeries and therapies.

6. Medical Wearable Devices: These PCB boards are utilized in wearable medical devices like fitness trackers, smartwatches, and remote patient monitoring devices. They enable data sensing, wireless communication, and integration with mobile applications for health tracking and management.

7. Medical Equipment Control Systems: PCB boards with soft-hard combination construction are used in control systems for medical equipment such as anesthesia machines, ventilators, surgical instruments, and infusion pumps. They provide the necessary circuitry for precise control, safety features, and user interfaces.