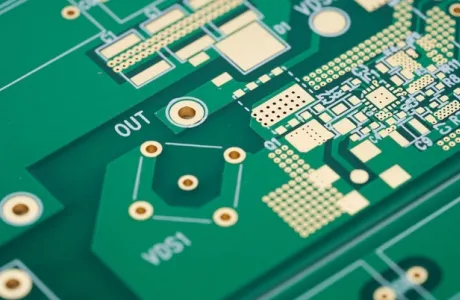

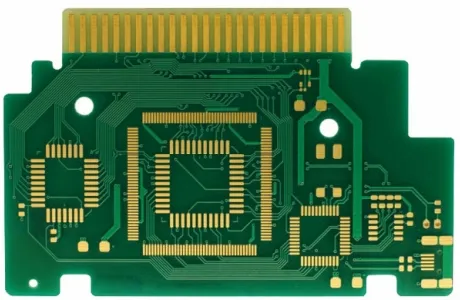

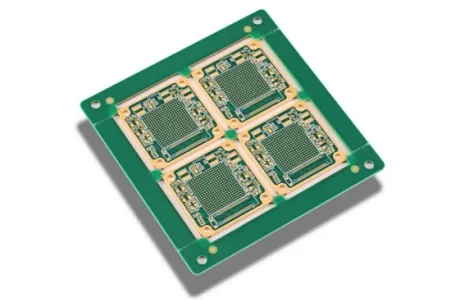

Double-sided Immersion Gold FR4 Medical PCB Circuit Board

Description :

Double-sided immersion gold FR4 PCB circuit board is a popular choice for various medical devices. It has reliable electrical connection, HDI capability, good corrosion resistance, and offers a cost-effective solution.Product Details:

Double-sided Immersion Gold FR4 Medical PCB Circuit Board

Double-sided immersion gold FR4 PCB circuit board is a type of printed circuit board that has conductive patterns on both sides of the insulating substrate. The FR4 material refers to a flame-retardant epoxy laminate that is commonly used in PCB manufacturing. The immersion gold finish is a surface treatment applied to the PCB to protect the copper traces and provide a reliable electrical connection.

The use of double-sided PCBs allows for more complex circuit designs as the conductive patterns on both sides can be interconnected through metallization holes. This feature is particularly useful in medical applications where intricate circuitry is often required. The immersion gold finish provides several benefits, including excellent solderability, corrosion resistance, and a flat surface for component placement.

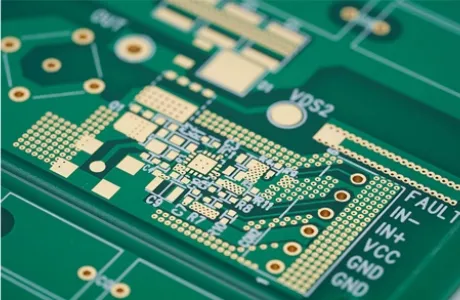

Double-sided Immersion Gold FR4 Medical PCB Circuit Parameter

| Number of layers | 2 |

| Substrate | FR4 |

| Thickness | 1.6mm |

| Surface Treatment | Immersion Gold |

| Special Process | / |

| Minimum aperture | 0.5mm |

| line width line spacing | 10/5mil |

| Applications | specifically designed for use in medical devices |

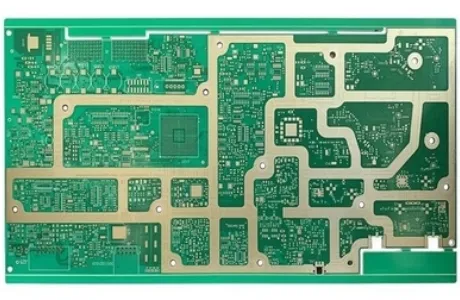

Double-sided Immersion Gold FR4 Medical PCB Circuit Board Advantages

Double-sided immersion gold FR4 medical PCB circuit boards offer several advantages that make them suitable for medical applications. Here are some key advantages:

1. Reliable Electrical Connection: The immersion gold finish provides excellent solderability, ensuring a reliable electrical connection between components and the PCB.

2. Good Corrosion Resistance: The immersion gold surface treatment protects the copper traces from corrosion, enhancing the longevity and performance of the PCB.

3. Flat Surface for Component Placement: The immersion gold finish creates a flat surface, making it easier to place and solder components onto the PCB.

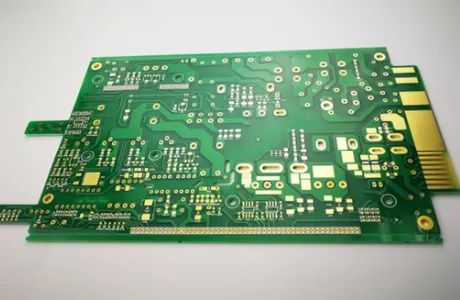

4. Compatibility with Various Applications: Double-sided immersion gold FR4 PCBs are compatible with a wide range of applications, including medical devices, consumer electronics, industrial control, automotive, and more.

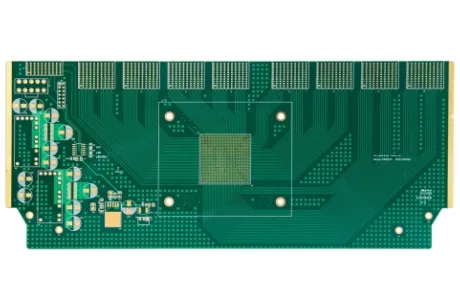

5. High-density Interconnect (HDI) Capability: Double-sided PCBs allow for more complex circuit designs and high-density interconnects, which are often required in medical applications.

6. Suitable for Fine Features: Immersion gold is ideal for PCB features with spacing below 150 microns and finer features below 100 microns.

7. Cost-Effectiveness: Immersion gold is commonly used in budget consumer electronics assemblies, making it a cost-effective choice for medical devices with shorter service life.

8. Compatibility with Multilayer Boards: Double-sided immersion gold FR4 PCBs can also be used as a part of multilayer boards, allowing for more complex and advanced circuit designs.

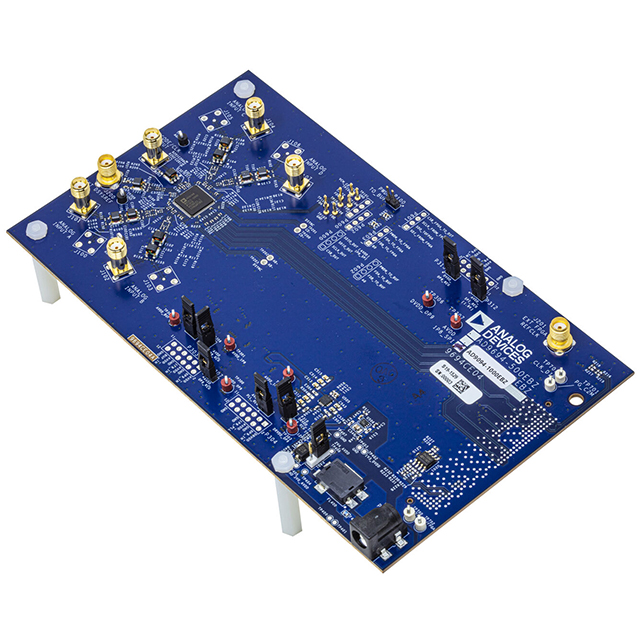

Double-sided Immersion Gold FR4 Medical PCB Circuit Board Applications

As its name suggests, double-sided immersion god FR4 medical PCB circuit board is widely used in the manufacturing of various medical equipment. They include diagnostic devices, patient monitoring systems, medical imaging equipment, laboratory instruments, and so on.