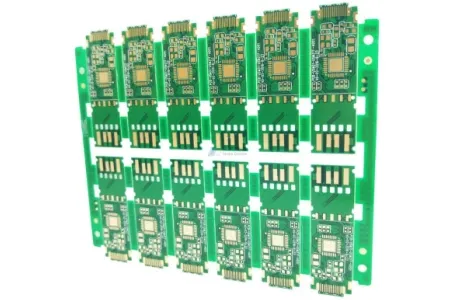

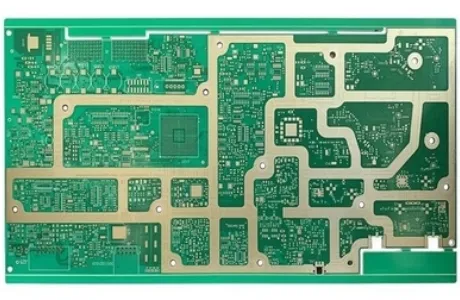

4-layer Immersion Gold FR4 Automotive PCB Circuit Board

Description :

4-layer immersion gold FR4 automotive PCB circuit board is a reliable and cost-effective solution for automotive electronics. Its multiple layers, gold immersion finish, and compact design make it suitable for applications that require high signal integrity and space efficiency. The manufacturing process involves lamination, etching, solder mask application, silkscreen layer, and surface finish.Product Details:

4-layer Immersion Gold FR4 Automotive PCB Circuit Board Introduction

4-layer immersion gold FR4 automotive PCB circuit board is a type of printed circuit board (PCB) that is specifically designed for use in automotive applications. It consists of four layers of conductive material separated by insulating layers, with a gold immersion finish on the surface. The FR4 refers to the type of material used as the base for the PCB, which is a flame-retardant fiberglass epoxy laminate.

4-layer Immersion Gold FR4 Automotive PCB Circuit Board Parameter

| Number of layers | 4 |

| Substrate | FR4 |

| Thickness | 1.6mm |

| Surface Treatment | Immersion gold |

| Special Process | impedance |

| Minimum aperture | 0.5mm |

| Inner layer line width and line spacing | 9/4mil |

| Outer layer line width and line spacing | 9/4mil |

| Applications | Automotive systems |

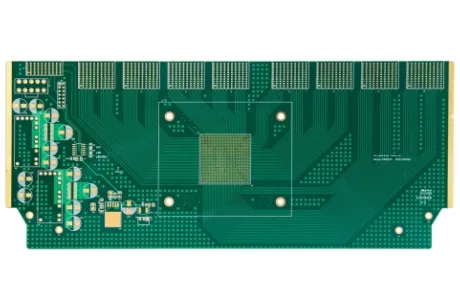

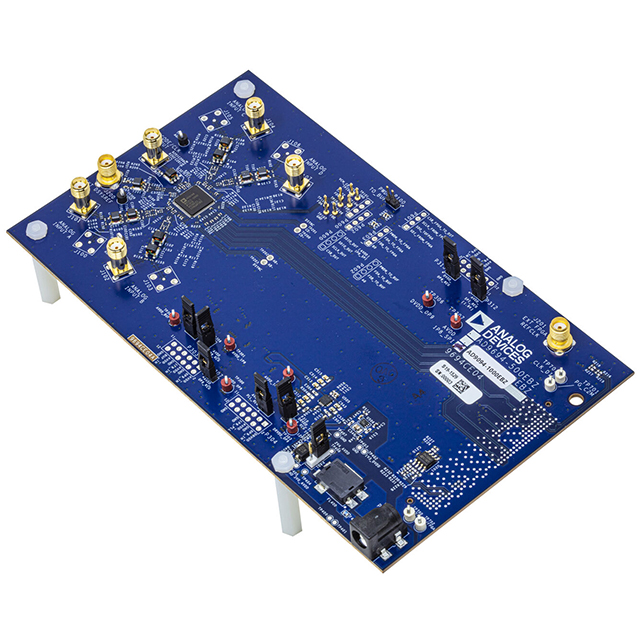

4-layer Immersion Gold FR4 Automotive PCB Circuit Board Benefits

The use of a 4-layer immersion gold FR4 automotive PCB circuit board offers several benefits:

1. Reliability: The FR4 material used in these PCBs provides good mechanical strength and excellent electrical insulation, making them highly reliable for automotive applications.

2. Signal Integrity: The multiple layers in the PCB allow for better signal integrity and reduced electromagnetic interference (EMI), which is crucial for automotive electronics.

3. Space Efficiency: The four-layer design allows for more compact circuitry and higher component density, making it suitable for applications with limited space.

4. Gold Immersion Finish: The gold immersion finish on the surface of the PCB provides a protective layer that enhances the PCB's durability and resistance to corrosion.

5. Cost-Effectiveness: 4-layer immersion gold FR4 automotive PCB circuit boards are cost-effective compared to other high-end PCB technologies, making them a popular choice for automotive electronics.

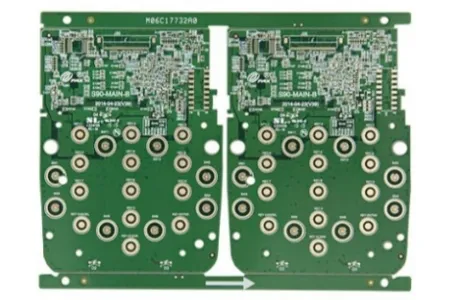

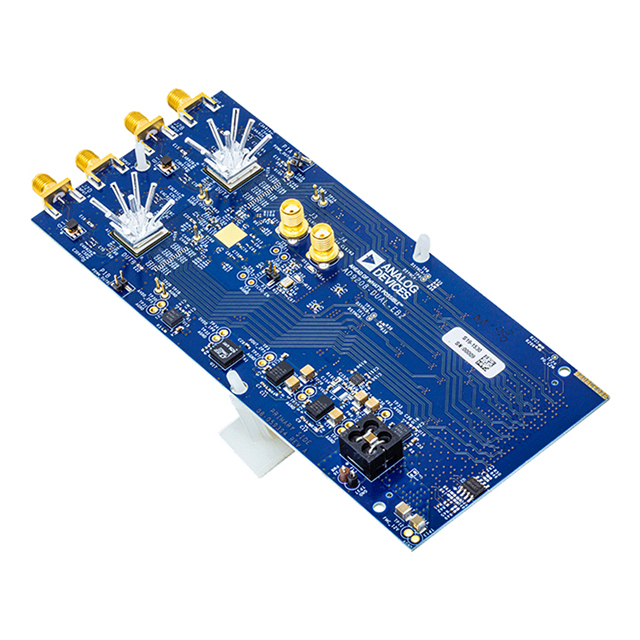

4-layer Immersion Gold FR4 Automotive PCB Circuit Board Manufacturing Process

The manufacturing process of a 4-layer immersion gold FR4 automotive PCB circuit board involves several steps:

1. Lamination: the FR4 board is laminated with one or more layers of copper foil using heat and adhesive. This copper forms the circuits in the finished product and may cover one or both sides, depending on the board's design.

2. Etching: the circuits are drawn and etched out from the copper layers, creating the desired circuit pattern.

3. Solder Mask Application: a solder mask layer covers the copper traces, leaving only the desired areas exposed for soldering.

4. Silkscreen Layer: the board is prepared for the final silkscreen layer, which includes labeling and component identification markings.

5. Surface Finish: the PCB undergoes a surface finish process, which in the case of a 4-layer immersion gold FR4 automotive PCB circuit board, involves applying a gold immersion finish to the exposed copper surfaces.

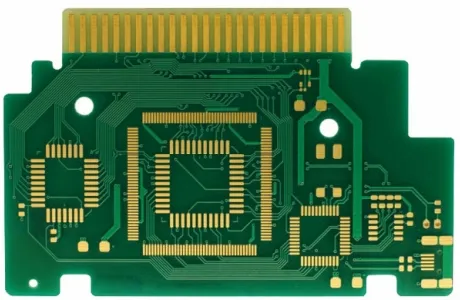

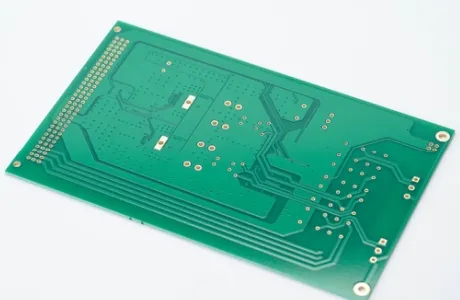

Double-sided Tin Spray FR4 Automotive PCB Circuit Board Applications

These circuit boards are widely used in automotive electronics due to their durability, reliability, and ability to withstand harsh operating conditions. They are used in various automotive systems such as engine control units (ECUs), powertrain control modules (PCMs), infotainment systems, and more.