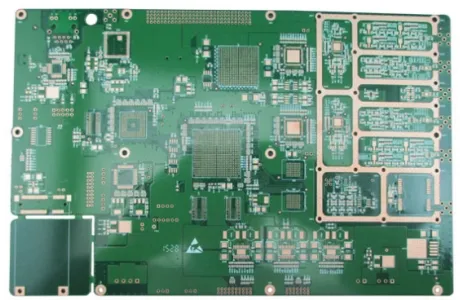

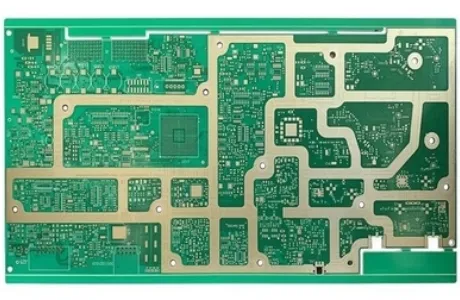

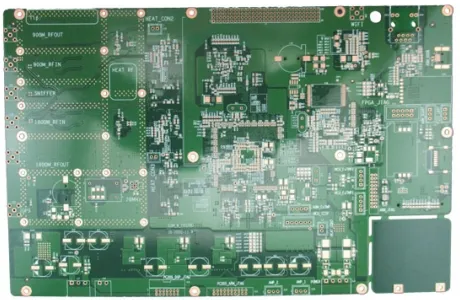

16-layer Immersion Gold High TG Industrial Control PCB Board

Description :

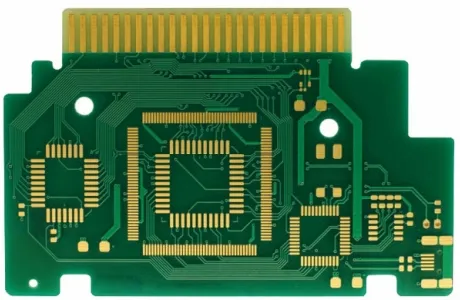

16-layer immersion gold high TG Industrial control PCB board is a type of printed circuit board used in industrial control applications. It is made of High Tg FR4, which refers to a type of flame-retardant fiberglass-reinforced epoxy laminate material with a high glass transition temperature. Additionally, the board features an immersion gold surface finishing, which is a coating applied to the surface of the PCB board through a chemical deposition process. It helps protect the copper traces from oxidation and provides a flat, solderable surface for components.Product Details:

16-layer Immersion Gold High TG Industrial Control PCB Board Introduction

16-layer immersion gold high TG industrial control PCB board is a type of printed circuit board used in industrial control applications. It is designed with 16 layers and features a high TG (glass transition temperature) and immersion gold surface finishing.

The immersion gold surface finishing is a coating between a component and a bare PCB circuit board. It is achieved through a chemical deposition process that produces a metal plating layer on the surface of the PCB board, effectively blocking copper and air oxidation.

16-layer Immersion Gold High TG Industrial Control PCB Board Parameter

| Number of layers | 16 |

| Substrate | FR4 TG170 |

| Thickness | 2.43mm |

| Surface Treatment | Immersion Gold |

| Special Process | / |

| Minimum aperture | 0.75mm |

| Inner layer line width and line spacing | 4/4mil |

| Outer layer line width and line spacing | 3.5/3.5mil |

| Applications | specifically designed for industrial control systems like industrial control core board |

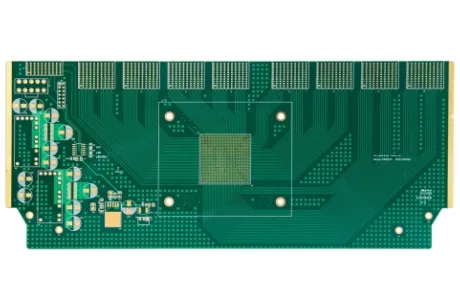

16-layer Immersion Gold High TG Industrial Control PCB Board Features

1. Temperature Resistance: The high TG (glass transition temperature) of the board allows it to withstand higher temperatures during pressing, resulting in a more durable and less brittle board.

2. Reliability: These boards are designed to provide high reliability and are suitable for mission-critical electronics like servers.

3. Immersion Gold Surface Finishing: The immersion gold coating on the board provides several benefits, including oxidation and corrosion resistance, good solderability, uniform coverage, suitability for complex designs, and cost-effectiveness.

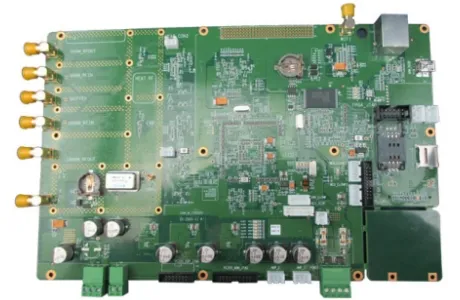

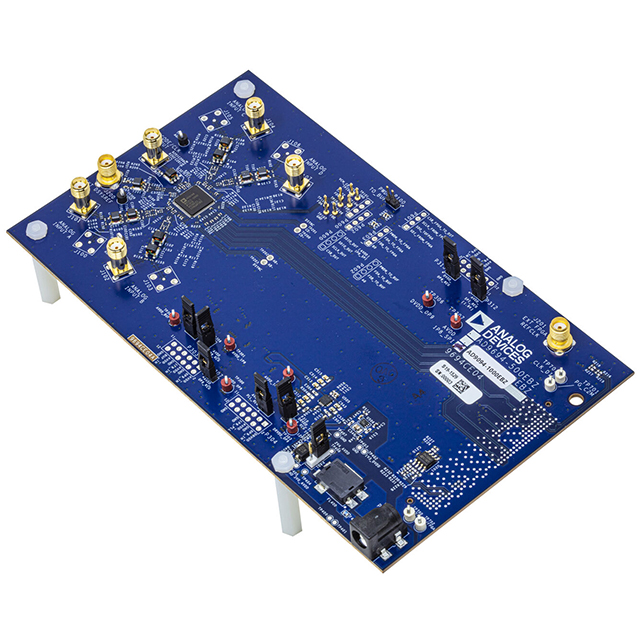

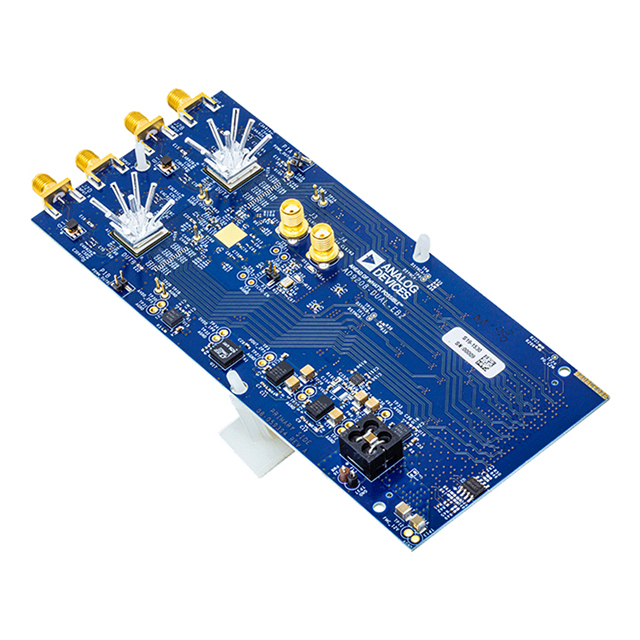

16-layer Immersion Gold High TG Industrial Control PCB Board Applications

16-layer Immersion Gold High TG Industrial Control PCB Board finds applications in various industrial control systems and high-end PCB designs. Here are some examples for your reference:

1. Industrial Control Systems: These PCB boards are specifically designed for industrial control applications, where they can be used in control panels, automation systems, robotics, and other industrial equipment.

2. High-End PCB Design: The boards are suitable for high-end PCB designs that require advanced features, such as high-speed, high-frequency, high-density, and high-difficulty designs.

Frequently Asked Questions about TG

1. What is TG?

TG refers to the glass transition temperature of the sheet material. At this temperature, the material alters its state or shape. It is usually a very high temperature. As we all know, the circuit board is generally flame-resistant; therefore, it cannot burn at a specific temperature. But it softens at a certain temperature. The temperature point at which the glass softens is called transition temperature (Tg point). This value is related to the dimensional stability of the PCB board. The higher the TG value, the better will be the temperature resistance of the sheet. Especially in the lead-free tin-spraying process, high Tg applications are more common.

2. When is it necessary to use a board with a high TG?

If the circuit has to operate at 150°C then a material with a Tg greater than or equal to 180°C is preferred. Such requirements are typically seen in mil-spec and space applications.

3. Why choose high TG PCB materials?

High Tg boards are generally more reliable than the standard FR-4 boards as they offer better thermal, chemical, and mechanical properties. This reduces the chances of short circuits and various other board failures in a high-temperature environment.