Top 9 Future Development Trends of Printed Circuit Boards (PCBs)

Generally speaking, the future development trends of printed circuit boards (PCBs) are influenced by technological advancements and the evolving needs of the electronics industry. Here are some key trends to watch out for.

1. High-density and Miniaturization

With the continuous pursuit of lightness, miniaturization, and high performance in electronic products, PCBs will be expected to become more miniaturized and high-density. This trend will drive continuous innovation in PCB design and manufacturing technology.

2. Flexibility

Flexible PCBs are becoming increasingly popular as they have better flexibility and bendability to adapt to different shapes and spaces than rigid PCBs. This makes them highly useful for modern-day electronics, including wearable devices, medical devices, cameras, and motion systems.

3. Intelligence

The future of PCBs will involve the gradual realization of intelligence. Embedded chips, sensors, and other technologies will enable PCBs to achieve self-detection, self-repair, and other functions, thereby improving the reliability of the boards.

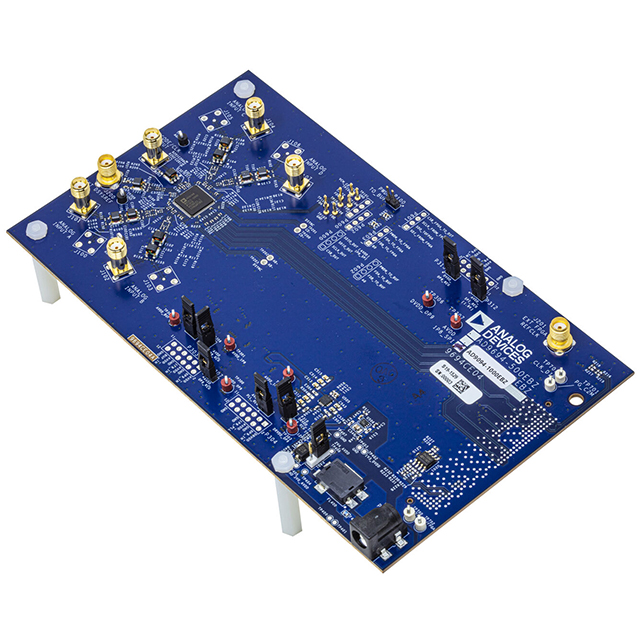

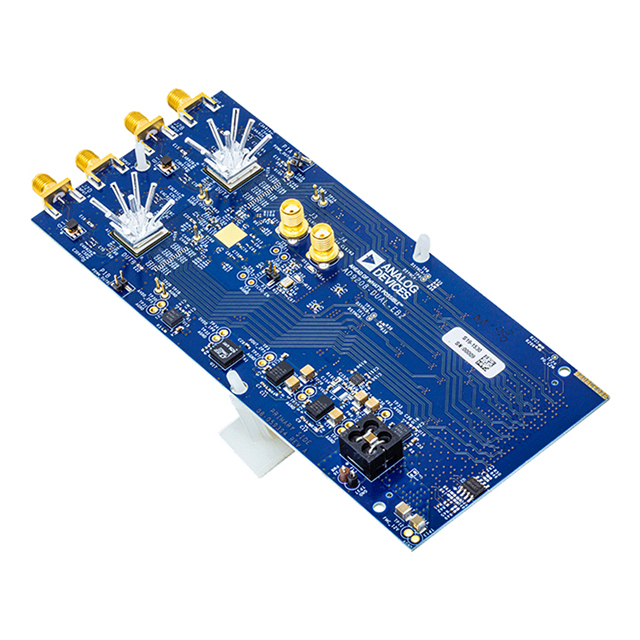

4. High-frequency and high-speed Signal Processing

As the demand for 5G communications, high-speed data transmission and high-performance computing grows, PCBs need to support higher frequencies and faster data transmission speeds, which will promote the development of high-frequency PCB materials and design technologies.

5. Artificial Intelligence and Automated Production in PCB Design and Manufacturing

Artificial Intelligence (AI) is revolutionizing PCB design and manufacturing processes. AI algorithms and machine learning techniques analyze vast amounts of design data, optimizing layout, routing, and manufacturing processes for improved efficiency and reliability. AI-enabled inspection systems detect defects and ensure stringent quality control, enhancing the overall reliability of PCBs.

6. 3D Printing

3D printing technology is making significant strides in the PCB industry. It offers the potential for more efficient and customizable PCB manufacturing processes. The adoption of photolithography processes or self-assembly for 3D printing is seen as a likely solution to address the challenges in PCB manufacturing.

7. Advanced Materials for Enhanced Performance

Advancements in material science have paved the way for superior PCB performance. Materials like ceramic and metal core laminates offer improved thermal conductivity, making them ideal for high-power applications. Nanomaterials and graphene-based conductive inks enhance signal integrity and enable faster data transmission, pushing the boundaries of PCB performance.

8. Customer Service Improvements

Alongside technological advancements, improvements in customer services are also changing PCB manufacturing. PCB manufacturers are adapting to meet the evolving needs and demands of customers, ensuring timely delivery, quality control, and efficient communication.

9. Environment Sustainable and Energy Saving

The future PCB will pay more attention to environmental protection and resource conservation. Adopting eco-friendly materials, manufacturing processes, and other measures to achieve environmental protection and energy-saving goals. For example, in response to the restrictions on harmful substances such as lead and cadmium, PCB manufacturers will use more environmentally friendly materials for manufacturing.

Conclusion

The PCB industry is undergoing a transformative phase, driven by the latest technological trends. From miniaturization and flexible PCBs to AI-enabled design and environmental sustainability, these trends are shaping the future of PCB circuit boards. Manufacturers and designers must stay abreast of these advancements to remain competitive and deliver innovative solutions. Embracing these trends will unlock new possibilities and drive exponential growth in various industries.

It is important to note that these trends are based on current observations and predictions. The PCB industry is dynamic, and new developments may emerge in the future.